827

FY 2011 Annual Progress Report

DOE Hydrogen and Fuel Cells Program

Jon P. Owejan (Primary Contact), Matthew Mench,

Michael Hickner, Satish Kandlikar, Thomas Trabold,

Jeffrey Gagliardo, Anusorn Kongkanand,

Wenbin Gu, Paul Nicotera

General Motors

10 Carriage Street

Honeoye Falls, NY 14472

Phone: (585) 953-5558

E-mail: [email protected]

DOE Managers

HQ: Donna Ho

Phone: (202) 586-8000

E-mail: [email protected]

GO: David Peterson

Phone: (720) 356-1747

E-mail: [email protected]

Technical Advisor

John Kopasz

Phone: (630) 252-7531

E-mail: [email protected]

Contract Number: DE-EE0000470

Subcontractors:

• PennStateUniversity,UniversityPark,PA

• UniversityofTennessee,Knoxville,TN

• RochesterInstituteofTechnology,Rochester,NY

Project Start Date: June 1, 2010

Project End Date: May 31, 2013

Fiscal Year (FY) 2011 Objectives

Characterize saturated relationships in state-of-the-art •

fuel cell materials.

Obtain a comprehensive down-the-channel validation •

data set for a baseline and auto-competitive material set.

Optimize component models to output bulk and •

interfacial transport resistances.

Demonstrate integrated transport resistances with a one •

plus one-dimension (1+1D) fuel cell model solved along

a straight gas flow path.

Identifycriticalparametersforlow-costmaterial•

development.

Technical Barriers

This project addresses the following technical barriers

from the Fuel Cells section of the Fuel Cell Technologies

ProgramMulti-YearResearch,Developmentand

Demonstration Plan:

(B) Cost

(C) Performance

(D) Water Transport within the Stack

Technical Targets

This project supports fundamental studies of fluid,

proton and electron transport with focus on saturated

operatingconditions.Insightsgainedfromthesestudies

are being used to develop modeling tools that capture

fundamental transport physics under single and two-phase

conditions.Thisprojectaddressestheexpectedoutcomes

from Topic 4a as follows:

Validated transport model including all component •

physical and chemical properties:

Down-the-channel pseudo-two-dimension (2D) –

model will be refined and validated with data

generated in the project.

Public dissemination of the model and instructions for •

exerciseofthemodel:

Project website to include all data, statistics, –

observations, model code and detailed instructions.

Compilation of the data generated in the course of •

model development and validation:

Reduceddatausedtoguidemodelphysicstobe –

published and described on project website.

Identicationofrate-limitingstepsand•

recommendations for improvements to the plate-to-

plate fuel cell package:

Model validation with baseline and auto- –

competitive material sets will provide key

performance limiting parameters.

FY 2011 Accomplishments

Generated distributed down-the-channel current, ohmic •

resistance, temperature and liquid water validation data

for a baseline material set.

Developed new characterization methods to measure •

transport relationships as a function of saturation.

Generated characterization data for bulk and interfacial •

transport in bulk membrane, thin ionomer films,

dispersed catalyst layers, gas diffusion layers and gas

delivery channels.

Developed wet model framework.•

V.F.4 Investigation of Micro- and Macro-Scale Transport Processes for Improved

Fuel Cell Performance

Owejan – General Motors

V.F Fuel Cells / Transport Studies

828

DOE Hydrogen and Fuel Cells Program

FY 2011 Annual Progress Report

Published validation and characterization data to a •

project website at: www.pemfcdata.org.

G G G G G

Introduction

The transport physics associated with fuel cell

operation is widely debated amongst researchers because

comprehensive micro/nano-scale process validation is

very difficult. Furthermore, fuel cell operation has a strong

interdependence between components making it difficult

to separate the key relationships required for predictive

modelswithexsitumethods.Generally,avalidatedmodel

that predicts operation based on known design parameters

for fuel cell hardware and materials is highly desired by

developers. Such a model has been proposed by many

research groups for dry (less than 100% relative humidity

[RH]exhaust)operationwithmoderatesuccess,however

these modelers unanimously assert that their ability to

predict wet operation is limited by two-phase component-

level understanding of transport processes. Additionally,

as two-phase models continue to be refined; benchmarking

progress is difficult due to incomplete validation datasets.

Inthecurrentwork,ourteamisdeveloping

characterization tools for saturated relationships based

on the evolution of a dry 1+1D model for accurate wet

prediction[1].Tocomplementthisworkwearealso

developing a comprehensive validation dataset based on

awideprotonexchangemembranefuelcell(PEMFC)

operating space. As data and modeling reach a final form,

these are uploaded to a project website at www.pemfcdata.

org. All characterization and validation work is conducted

with a common material set.

Approach

Thisprojectisorganizedaroundbaselineandnext-

generation material sets. These materials define parametric

bounds for component and integrated down-the-channel

modeling efforts. The baseline material set was chosen

basedonthecommercialstateoftheartthatexiststoday.

Thenext-generationmaterialsetconsistsoftransport

impacting parametric changes that are in-line with the DOE

2015 targets for reduced cost while improving durability

and performance. For characterization and validation

experiments,astandardprotocolwasalsodevelopedto

enabletheteamtoconductexperimentswiththesame

boundary conditions.

Therstphaseofthisprojectwasexperimentally

focused on characterization work that is organized by

transport domain, comprising thin film ionmers, bulk

membranes, porous electrodes, gas diffusion layers and

flow distribution channels. More specifically, the key

relationships being investigated are outlined as follows:

IonomerCharacterization•

Membrane water uptake, water diffusivity and –

hydraulic permeability.

Oxygenandwatertransportasafunctionof –

ionomer layer thickness.

Evidence of nanophase/water morphological –

changes vs. film thickness.

Diffusion Layer Characterization •

Microporous layer thermal conductivity and D/D –

eff

as a function of saturation.

Catalyst layer liquid water pressure as a function of –

saturation, pore size, and hydrophobicity.

Substrate thermal conductivity (wet and dry) and –

D/D

eff

as a function of saturation.

Through-plane saturation and wet region boundary –

as a function of dT and operating temperature.

Channel Characterization •

Carbon fiber paper (CFP) to channel interfacial –

transport resistance as a function of channel

saturation.

Channel dP as a function of saturation, –

temperature, flow, and current density.

Manifold dP as a function of saturation, –

temperature, and flow.

These relationships are required to develop component

models that output bulk and interfacial transport resistances

totheproject1+1Ddown-the-channelmodel.Inanticipation

of this integrated model, a validation data set is being

collected in parallel with small scale hardware specifically

designedtoincludeautomotivestackconstraints[2].

Results

Project Website

The project website was made available to the public at

www.pemfcdata.org. This information tool is designed for

sharing project data and modeling with the broader fuel cell

research community to provide a common validation tool

that generates dialog about fundamental transport physics in

PEMFCs. A navigational map of the current website is given

in Figure 1.

This website contains a ‘Home’ and ‘Project’ page

that describes the funding, participants, news, approach,

deliverables, standard materials and testing protocol. The

‘Macro’ page contains the down-the-channel validation

dataforthebaselinematerialsetandthenext-generation

materialsetwillbeuploadedinthenextphaseofthe

project. The ‘Micro’ page is continuously being updated

with characterization data as it becomes available. The list

of model parameters is posted to the ‘Parameters’ page. This

list is currently posted for the dry-based model only, which is

available on the ‘Modeling’ page (the wet model is currently

being developed and will be posted in the second phase

829

FY 2011 Annual Progress Report

DOE Hydrogen and Fuel Cells Program

V.F Fuel Cells / Transport Studies

Owejan – General Motors

of the project). Finally, the ‘Contact’ and ‘FAQ’ pages are

intended to initiate dialog regarding our data and approach.

Baseline Validation Data

Experimentalvariabilitywascarefullyexaminedprior

to collecting the baseline material set data for the 117

point standard protocol. With regard to the controlled test

parameters, temperature control with cartridge heaters was

found to have the most significant impact on test variation.

RHuctuationswithinthecellresultfromtemperature

variations as heaters cycle, and this impacts all aspects of

transport within the cell. Liquid coolant with flow and

temperaturecontrolwasusedtomitigatethisexperimental

variability, which was confirmed with our temperature

distribution tool by comparing the temperature distributions

with and without coolant. This comparison showed

a constant temperature profile is achieved with liquid

coolant. Moreover, the temperature distribution is more

representative of a commercial fuel cell system with coolant,

as the temperature gradient should increase toward the

coolant outlet side. For this reason, most 50 cm

2

validation

experimentswillutilizeliquidcoolantduringthecourseof

the project.

The validation data set includes distributed liquid

water, current, high frequency resistance and temperature

measured across the active area. Additionally, anode vs.

cathode water balance based on condensed outlet water was

collected for each test point. A tool (shown in Figure 1) was

developed to navigate this database such that our team and

other interested researchers can select a test point from the

standard protocol to download the raw and processed data.

Currently the validation dataset is fully populated for the

baseline material set.

Transport in Thin Ionomer Films

Ellipsometric, microbalance, and fluorescence

measurements on thin Nafion

®

films have been performed

on model surfaces. These characterization techniques on

ionomer films with thicknesses between 30 and 600 nm are

designed to probe the transport and swelling properties of

the thin ionomer films in the catalyst layers. Ellipsometry

and microbalance measurements can give us highly accurate

measurements of the water content and swelling of these

lmsasafunctionofRH.Theuorescencemeasurements

shed light on the dynamics of the film, which governs the

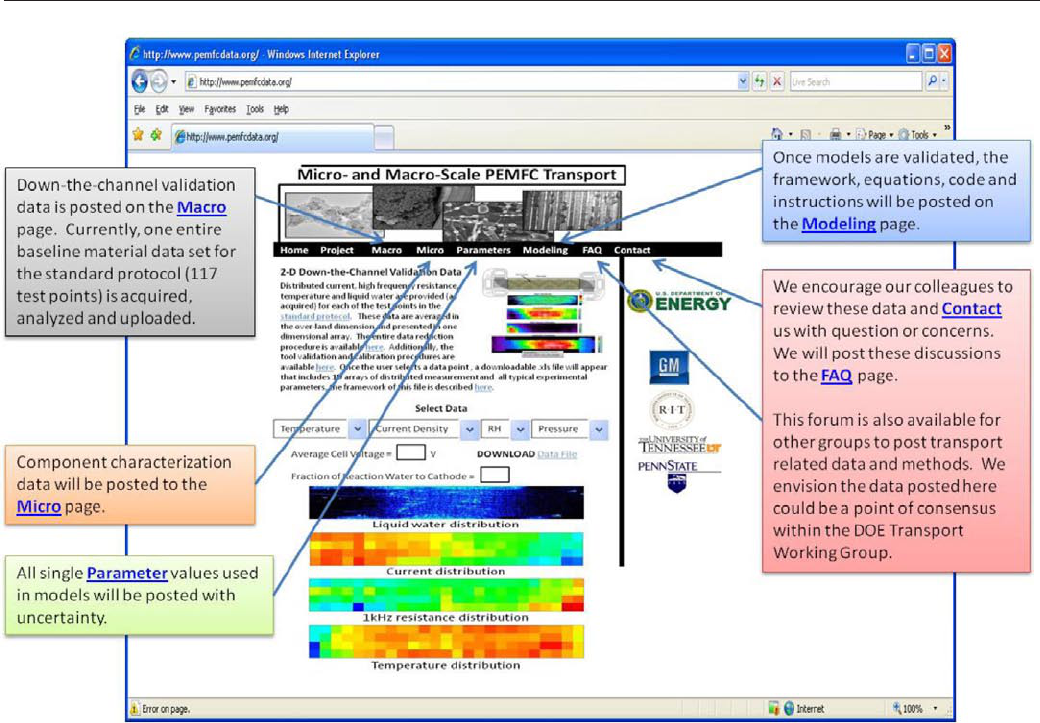

Figure 1. Project Website Navigational Map

Owejan – General Motors

V.F Fuel Cells / Transport Studies

830

DOE Hydrogen and Fuel Cells Program

FY 2011 Annual Progress Report

water self-diffusion and transport properties. Fluorescence

measurements probe the dynamics in the aqueous domains

and we have also used grazing incidence small-angle X-ray

scattering to probe their structure. Both the water uptake or

hydration number (λ) and self-diffusion of water within the

lmdeterminesitsoxygenandprotontransportproperties

as these species move through the aqueous domains of

the material. Select microbalance and fluorescence are

presented herein to demonstrate the sensitivities being

observed in thin films.

Microbalance results shown in Figure 2a indicate that

water content for different film thicknesses was similar for

Nafion

®

lmsongoldthickerthan500nm[3].Atlower

thicknesses, slightly lower water contents were observed,

especially at high vapor water activities. The origin of

the observed depression in water content is still unclear.

InteractionoftheionomerwiththeAusubstratecould

constrain the film from swelling, which is essential for water

sorption.Itisalsoconceivablethatawaterimpermeable

layer (disordering of water channels) at the gas/ionomer

interface may contribute to the observation. Fluorescence

intensitymeasurementsof9-([E]-2-carboxy-2-cyanovinyl)

julolidine (CCVJ) in thin Nafion

®

films given in Figure

2b show that the fluorescence response is a function of

thickness.HigherI/Ioresponseindicatesstiffeningof

the film upon water uptake which is not observed for the

membrane,buthasbeenreportedforotherthinlms[4].

Since the CCVJ fluorescence signal is controlled by the

local viscosity or mobility of the sample, it can be used to

measurewaterdiffusioninpolymers[5].TheI/Iosignal

will be related to the self-diffusion coefficient of water in

thenextphaseofthiswork.Thesemeasurementsindicate

different water dynamics in thin and thick films and provide

fundamental information on potential differences in proton

conductivity and other transport properties as a function of

film thickness.

Transport in Diffusion Materials

Severalinsituandexsitumeasurementsarebeing

used to measure transport in the porous components that

include the electrode, microporous layer and carbon fiber

macroporoussubstrate.Insituneutronimaging,infrared

imaging and acoustic microscopy are being used to map

through-plane liquid water distributions within the anode

vs.cathodediffusionlayers.Exsituworkisfocusedon

thermal conductivity and mass diffusivity as a function of

water saturation, and capillary pressure relationships for the

baseline diffusion media and catalyst layer are underway.

Uniquetestcellsandmethodologycapableofcontrolling

saturation have been developed to complete this testing.

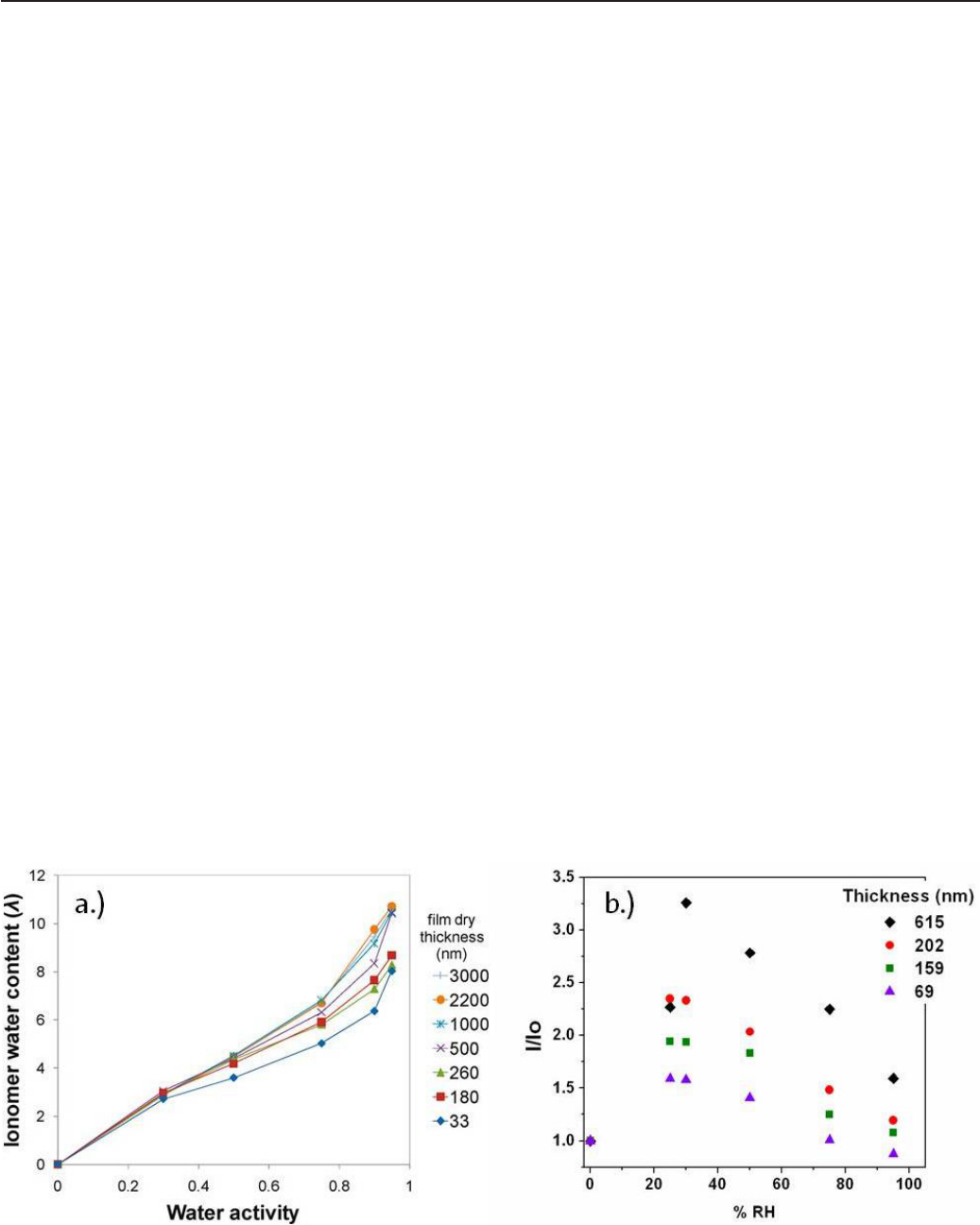

One characteristic result from the standard protocol

has been selected for presentation in this paper and the

complete reduced data set has also been made public at the

website. Measured with high resolution neutron imaging,

Figure 3a shows the effect of anode vs. cathode outlet

pressure differentials on water saturation. The operating

temperature is 40

0

C,anode/cathodeRHis95/95%andthe

current density is 0.8 A/cm

2

.Itisevidentfromtheplothow

the higher pressure on the cathode side shifts the saturation

towards the anode and vice versa. These data provide

insightintothecomplexwaterbalancetobemodeled.The

corresponding voltages have also been recorded in the

plot. Polarization curves obtained with fast scans after each

operating condition (Figure 3b) demonstrate the effect of the

pressure differential on performance. The false color images

in Figure 3c show the regions of water accumulation relative

to the land/channel geometry for the specific operating

conditions. These data also indicate how sensitive anode gas

diffusion layer (GDL) saturation is, and this is not typically

considered in two-phase models to this point.

Figure 2. Water interaction with varying thicknesses of thin Nafion

®

films as a function of water activity: a) water uptake at 80°C, b) CCVJ fluorescence

response at 25°C.

831

FY 2011 Annual Progress Report

DOE Hydrogen and Fuel Cells Program

V.F Fuel Cells / Transport Studies

Owejan – General Motors

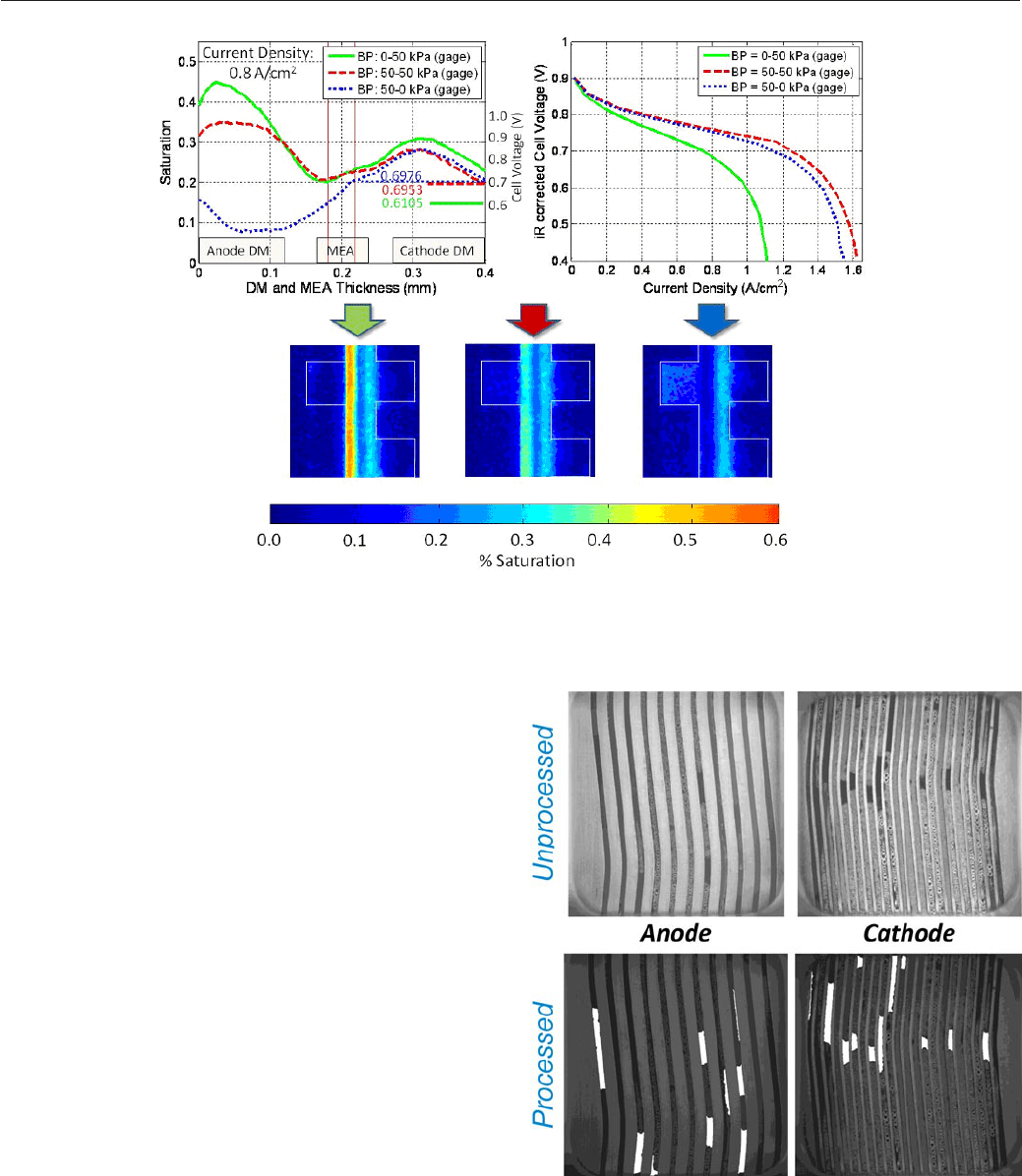

Transport in Flow Distributor Channels

Two key components of the down-the-channel model

are the relationships between channel water saturation

and both CFP to channel interfacial transport resistances,

and the channel pressure drop. Therefore, it is critical to

establish a well-defined channel water saturation metric. A

technique has been developed to quantify the in situ channel

water saturation through the combined utilization of high

speed videos of the flow field channels during operation and

digitalimageprocessing[6].Theimageprocessingalgorithm

automatically detects static and dynamic liquid water, and

also characterizes the flow structure of each water object.

The water coverage ratio parameter along with channel

pressure drop as a function of saturation are providing

crucial information pertaining to transport resistance

associated with liquid water accumulation in the flow field

channels. Sample images showing pre- and post-processed

flow field channels and the resulting water detection are

showninFigure4.Inadditiontothischaracterizationof

wateradjacenttotheCFPintheactivearea,experiments

are underway to characterize the resistance of liquid water

transitioning from the bipolar plate micro-channels in the

gas manifolds of a fuel cell stack. Here the combination

of low gas shear and contact line pinning has been found

to cause water stagnation at the plate edge. This results

in additional plate-to-plate flow variations that must be

captured in a true two-phase fuel cell model.

Figure 3. Impact of varied outlet pressure: a) GDL water saturation and through-plane, b) polarization curves,

c) false color images showing saturation.

Figure 4. Representative unprocessed and processed high speed images

of liquid water distribution in both anode and cathode channels. The

processed images can provide quantified information of local and overall

water coverage ratio.

Owejan – General Motors

V.F Fuel Cells / Transport Studies

832

DOE Hydrogen and Fuel Cells Program

FY 2011 Annual Progress Report

FY 2011 Publications/Presentations

1.J.Gagliardo,J.Fagley,D.Fultz,J.Owejan,“Inuence

of Through-Plane Thermal Profile on Water Accumulation

inProtonExchangeMembraneFuelCells”Meetingofthe

Electochemical Society, Las Vegas, NV. October 2010.

2. Jacob M LaManna, Fengyuan Zhang, Subhadeep

Chakraborty, and Matthew M. Mench, Quantification of

Through-Plane Liquid Water Gradients and Transport in

PEFCswithHighResolutionNeutronImaging.Acceptedfor

Presentation, 2011 ECS Meeting, Montreal Canada.

3.

ZijieLu,CodyRath,GuangshengZhang,

Satish G. Kandlikar. Water management studies in PEM fuel

cells,partIV:Effectsofchannelsurfacewettability,geometry

and orientation on the two-phase flow in parallel gas channels,

InternationalJournalofHydrogenEnergy(2011).

4.Kongkanand,A.,“InterfacialWaterTransportMeasurements

inNaonThinFilmsUsingaQuartz-CrystalMicrobalance,”

J. Phys. Chem. C, 115, pp. 11318-11325, (2011).

5. Sergi, J.M., Kandlikar, S.G., “Quantification and

Characterization of Water Coverage in PEMFC Gas Channels

UsingSimultaneousAnodeandCathodeVisualizationand

ImageProcessing,”InternationalJournalofHydrogenEnergy,

Accepted Manuscript, 2011.

6.

J.Owejan,DOEAnnualMeritReview,ArlingtonVA,May

12, 2011.

References

1.Gu,W.,Baker,D.R.,Liu,Y.,Gasteiger,H.A., “Proton

exchangemembranefuelcell(PEMFC)down-the-channel

performancemodel,”Handbook of Fuel Cells - Volume 5, Prof.

Dr. W. Vielstich et al. (Eds.), John Wiley & Sons Ltd., (2009).

2. Owejan, J.P., Gagliardo, J.J., Sergi, J.M., Kandlikar, S.G.,

Trabold, T.A., “Water management studies in PEM fuel

cells,PartI:Fuelcelldesignandinsituwaterdistributions,”

InternationalJournalofHydrogenEnergy,34(8),pp.3436-

3444, (2009).

3.

Kongkanand,A.,“InterfacialWaterTransportMeasurements

inNaonThinFilmsUsingaQuartz-CrystalMicrobalance,”

J. Phys. Chem. C, 115, pp. 11318-11325, (2011).

4.Nolte,A.J.;Treat,N.D.;Cohen,R.E.;Rubner,M.F.

Macromolecules, 41, 5793–5798, (2008).

5.

Miller,K.E.;Krueger,R.H.;Torkelson,J.M.,J.Polym.Sci.:

Polym. Phys, 33, 2343-2349, (1995).

6. Sergi, J.M., Kandlikar, S.G., “Quantification and

Characterization of Water Coverage in PEMFC Gas Channels

UsingSimultaneousAnodeandCathodeVisualizationand

ImageProcessing,”InternationalJournalofHydrogenEnergy,

Accepted Manuscript, 2011.

To optimize the channel design for better water

management, the effects of channel surface wettability,

cross-sectional geometry and orientation on the two-phase

owinparallelgaschannelswereinvestigated.Itwasfound

that hydrophilic channels are advantageous over uncoated

or slightly hydrophobic channels in terms of uniform water

and gas flow distribution and promoting film flow. Stamped

metal geometry channels favor film flow when compared

to a rectangular geometry. Vertical channel orientation is

advantageous over horizontal orientation because it is less

prone to slug flow, and facilitates more uniform liquid water

distribution and stable operation.

Conclusions and Future Directions

A well organized characterization, modeling and

validation framework was developed early in this project.

Therstphaseofexecutionwaslargelyfocusedon

experimentaldevelopmentwithkeyaccomplishments

outlined as follows:

Project is standardized by materials and operating space:•

Baseline and auto-competitive material sets chosen

–

based on parametric variations that consider

degradation and cost vs. performance trade-offs.

Key relationships required for a wet 1+1D model and •

characterization methods are defined:

Subjectmatterexpertsaredevelopingandexecuting –

characterization methods to generate physical

understanding of fundamental processes.

Component models describing processes are being

–

generated and will be used to output bulk and

interfacial transport resistances.

Modeling framework for 1+1D model is defined.

–

Down-the-channel baseline material validation data set •

complete:

Additionalrepeatexperimentsbeingexecutedto –

define uncertainty.

Database on the website for dissemination of data and •

modeling:

Visit www.pemfcdata.org (development will

–

continue throughout the project).

Thenextphaseofthisprojectisfocusedonrening

the component and down-the-channel models in parallel

while repeating characterization and validation work for the

next-generationmaterialset.Thisworkwillsupportthekey

deliverablefornextyear:avalidated1+1Dmodelcapableof

predicting performance and water balance under saturated

conditions with baseline material parameters.