V–151

FY 2014 Annual Progress Report

DOE Hydrogen and Fuel Cells Program

Wenbin Gu (Primary Contact), Matthew Mench,

Michael Hickner, Satish Kandlikar, Thomas Trabold,

Jeffrey Gagliardo, Anusorn Kongkanand,

Vinod Kumar, Ruichun Jiang, Swami Kumaraguru

General Motors

895 Joslyn Ave.

Pontiac, MI 48340

Phone: (585) 953-5552

Email: wenbin.gu@gm.com

DOE Managers

Donna Ho

Phone: (202) 586-8000

Email: Donna.Ho@ee.doe.gov

David Peterson

Phone: (720) 356-1747

Email: David.Peterso[email protected]

Technical Advisor

John Kopasz

Phone: (630) 252-7531

Email: kopasz@anl.gov

Contract Number: DE-EE0000470

Subcontractors

• PennStateUniversity,UniversityPark,PA

• UniversityofTennessee,Knoxville,TN

• RochesterInstituteofTechnology,Rochester,NY

• UniversityofRochester,Rochester,NY

Project Start Date: June 1, 2010

Project End Date: May 31, 2014

Overall Objectives

Investigate and synthesize fundamental understanding of

transport phenomena at both the macro- and micro-scales for

the development of a down-the-channel model that accounts

for all transport domains in a broad operating space.

Fiscal Year (FY) 2014 Objectives

Characterize saturated relationships in state-of-the-art •

fuel cell materials.

Obtain a comprehensive down-the-channel validation •

dataset for a parametric study material set.

Develop multidimensional component models to output •

bulk and interfacial transport resistances.

Demonstrate integrated transport resistances with a one •

plus one-dimension (1+1D) fuel cell model solved along a

straightgasowpath.

Identify critical parameters for low-cost material •

development.

Technical Barriers

This project addresses the following technical

barriers from the Fuel Cells section of the Fuel Cell

TechnologiesOfceMulti-YearResearch,Development,and

Demonstration Plan:

(B) Cost

(C) Performance

Technical Targets

Thisprojectsupportsfundamentalstudiesofuid,

proton and electron transport with a focus on saturated

operating conditions. Insights gained from these studies

are being used to develop modeling tools that capture

fundamental transport physics under single and two-phase

conditions. The primary deliverables are:

Validated cell model including all component physical •

and chemical properties.

Public dissemination of the model and instructions for •

exerciseofthemodel.

Compilation of the data generated in the course of model •

development and validation.

Identicationofrate-limitingstepsandrecommendations•

for improvements to the plate-to-plate fuel cell package.

FY 2014 Accomplishments

Obtained validation data set for baseline materials with •

low Pt-loaded cathode

Establishedorrenedseveralone-dimensional•

relationships based on parametric and characterization

methods developed within the project.

Demonstrated improved down-the-channel 1+1D model •

prediction with new relationships integrated.

Published validation, parametric studies, and •

characterization data to a project website at: www.

pemfcdata.org.

G G G G G

V.G.3 Investigation of Micro- and Macro-Scale Transport Processes for

Improved Fuel Cell Performance

Gu – General Motors

V.G Fuel Cells / Transport Studies

V–152

DOE Hydrogen and Fuel Cells Program

FY 2014 Annual Progress Report

INTRODUCTION

The transport physics associated with fuel cell

operation are widely debated amongst researchers because

comprehensive micro/nano-scale process validation is very

difcult.Furthermore,fuelcelloperationhasastrong

interdependencebetweencomponentsmakingitdifcultto

separate the key relationships required for predictive models

withexsitumethods.Generally,avalidatedmodelthat

predicts operation based on known design parameters for fuel

cell hardware and materials is highly desired by developers.

Such a model has been proposed by many research groups

fordry(lessthan100%relativehumidityexhaust)operation

with moderate success; however these modelers unanimously

assert that their ability to predict wet operation is limited

by two-phase component-level understanding of transport

processes. Additionally, as two-phase models continue to be

rened,benchmarkingprogressisdifcultduetoincomplete

validation datasets.

In the current work, our team is developing

characterization tools for saturated relationships based on the

evolution of a dry 1+1D model for accurate wet prediction

[1]. To complement this work we are also developing a

comprehensive validation dataset based on a wide proton

exchangemembranefuelcell(PEMFC)operatingspace.As

dataandmodelingreachanalform,theseareuploadedtoa

project website at www.pemfcdata.org. All characterization

and validation work is conducted with common material sets

thatrepresentcurrentandnextgenerationsofPEMFCdesign.

APPROACH

Thisprojectisorganizedaroundbaselineandnext-

generationmaterialsets.Thesematerialsdeneparametric

bounds for component and integrated down-the-channel

modeling efforts. The baseline material set was chosen based

onthecommercialstateoftheartthatexiststoday.The

next-generationmaterialsetconsistsoftransportimpacting

parametric changes that are in line with the DOE 2015 targets

for reduced cost while improving durability and performance.

Forcharacterizationandvalidationexperiments,astandard

protocol was also developed to enable the team to conduct

experimentswiththesameboundaryconditions.

Therstphaseofthisprojectwasexperimentally

focused on characterization work that is organized by

transportdomain,comprisingthinlmionomers,bulk

membranes, porous electrodes, gas diffusion layers (GDLs)

andowdistributionchannels.Thespecicsofthese

relationships were outlined previously [2]. In anticipation of

this integrated model, validation data sets are being collected

inparallelwithsmallscalehardwarespecicallydesigned

to include automotive stack constraints [3]. Currently with

theseexperimentalmethodsestablished,workbecomesmore

modeling focused as the physical mechanisms that govern

the observed transport phenomenon are described multi-

dimensionally at the component level and evaluated with a

1+1D fully integrated model. This work continuously guides

parametric studies with novel material changes.

RESULTS

Validation Data

In the auto-competitive material set tested for model

validation, a number of parameters, including membrane

thickness, anode GDL, cathode catalyst layer composition,

oweldland/channelgeometryandmanifoldexitheaders,

are changed from the baseline material set. Hence, the

performance difference between the two material sets

represents a compounded effect of all changes being made

at once. To de-convolute the effects of high diffusion

resistance anode GDL and cell design differences used in

DOE automotive competitive cell builds from low Pt-loaded

cathode catalyst layer effects, a parametric study cell built

with low Pt-loaded cathode and other baseline materials was

tested using the standardized project protocol that varies

outlet temperature, inlet relative humidity, outlet pressures,

and current density [4]. Compared to the baseline cell, the

parametric study cell yielded lower cell voltage and less

productwatertothecathodeoweld.Thelowervoltage

results primarily from lower Pt loading and slightly higher

high-frequency resistance (HFR). And less product water to

thecathodeoweldappearstobeconsistentwithhigher

temperature gradient caused by the lower cell voltage and

thus higher heat generation rate. However, both baseline and

parametric study cells demonstrate same trend in down-the-

channel current distribution, suggesting that lower Pt-loaded

cathode in the auto-competitive material set would not be

responsible for the opposite trend in current distribution

associated with the auto-competitive cell at low temperatures.

Instead, the highly tortuous anode diffusion medium is most

likely the cause.

Transport in Thin Ionomer Films

With focus on elucidating the structural features

andtransportpropertiesofthinionomerlms,wehave

performedextensivegravimetricandvolumetricswelling

studiestounderstandhowthesethinlmsbasedon

peruorinatedsulfonicacid(PFSA)ionomersuptakewater

andhavecomparedthepropertiesofthinionomerlmsto

what is known about PFSA-based membranes. The focus on

water uptake and swelling is because the transport properties

of these materials is determined in large part by their

hydration. We have found that the water uptake of PFSA-

basedthinlmsvarieswiththickness,substratetype,and

processing conditions. To understand the swelling processes

in more depth, we have undertaken measurements of polymer

chain alignment using Fourier transform infrared (FTIR) and

ellipsometry. These techniques were chosen because they

can be adapted to electrochemical measurements to study

V–153

FY 2014 Annual Progress Report

DOE Hydrogen and Fuel Cells Program

V.G Fuel Cells / Transport Studies

Gu – General Motors

thebehaviorofthinlmsunderpotentialcontrol,which

is ongoing work. Shown in Figure 1 is the FTIR spectra of

50-nmand5-nmNaon

®

lms.TheSO

3

/CF

3

side chain peaks

areenhancedinthethinlmspectraindicatingalignment

ofthesemoietiestowardsthesurfaceinthethinnestlms

[5]. Similar observations have been made by studying

thebirefringenceofNaon

®

lmsusingspectroscopic

ellipsometry [6]. Our goal is to be able to measure the

dynamicbehaviorofthesethinlmsasafunctionof

potential, which can be detected by changes in their FTIR or

ellipsometric spectra. These types of measurements focusing

on the features of the ionomer-substrate interface may lead to

abetterunderstandingofwhytheoxygentransportresistance

at low platinum loading occurs. This work on the structure of

thethinlmsandhowthestructurecorrelateswithswelling

and ultimately other transport properties complements

our collaborative work with Lawrence Berkeley National

Laboratoryonscatteringstudies[7]asafunctionoflm

processing conditions and substrate type.

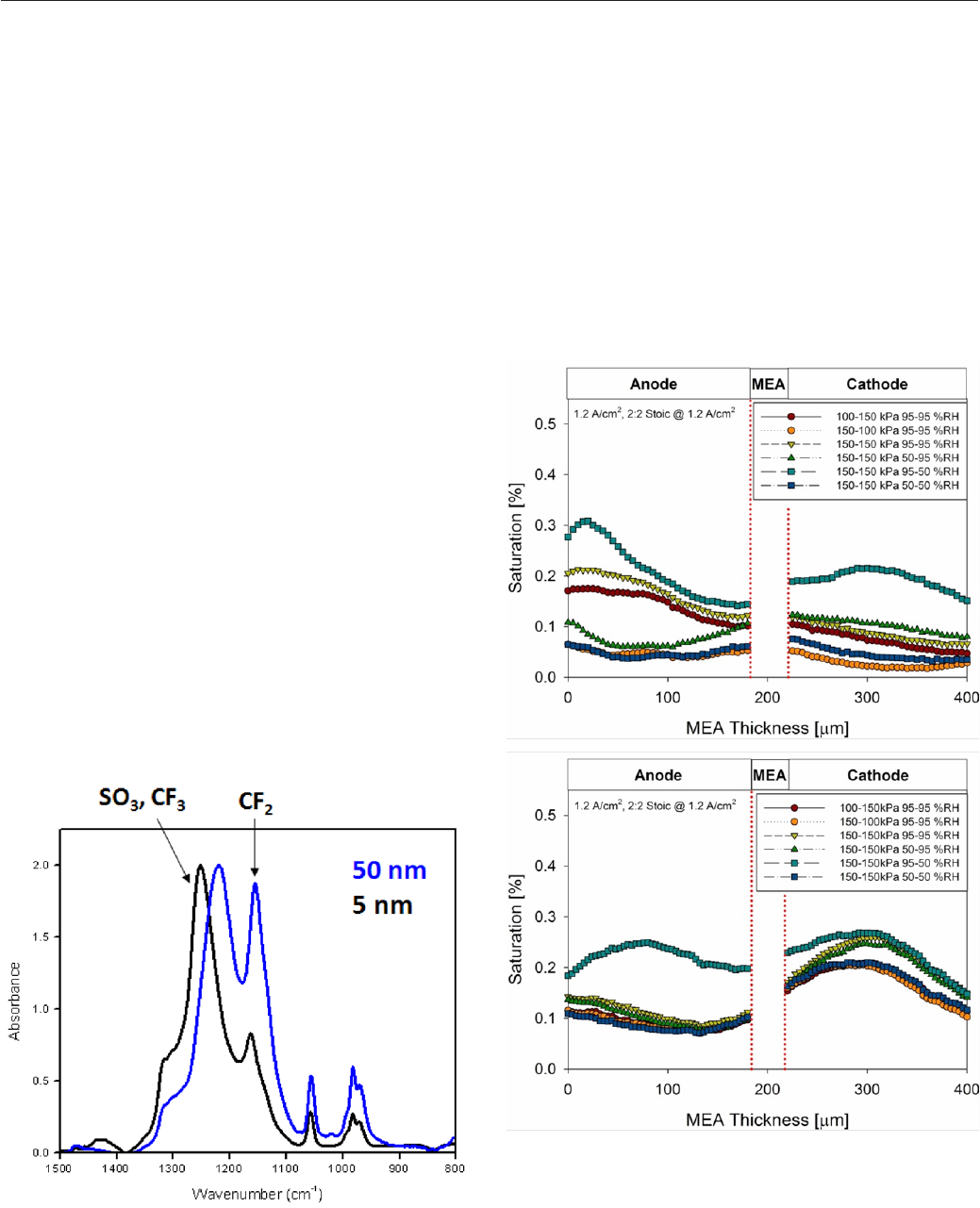

Transport in Diffusion Materials

We developed an empirical relationship for effective

thermal conductivity of partially saturated diffusion

mediaviaexsitumaterialtesting[8].Additionally,we

experimentallydeterminedcapillarydrainagefunctions

of liquid water from the catalyst layer, micro-porous

layer,andtheinterfacialdomains[9].Utilizingthehigh

resolution neutron imaging facility at the National Institute

ofStandardsandTechnology,wecompletedextensivein

situ characterization of the impacts of diffusion media

design,ow-eldinterfacearchitecture,andaging,covering

anextremelywiderangeofoperationaltestconditions.In

particular, diffusion media aged in situ for over 2,500 hours

has been tested with neutron imaging and show additional

water storage during operation. The water balance was found

to shift in the aged material from the anode to the cathode, as

shown in Figure 2. To understand what has caused the change

in water balance, energy dispersive X-ray spectroscopy and

X-ray photoelectron spectroscopy were used to determine

changes in chemical makeup and surface morphology. The

resultsindicateanincreaseincarbon-oxygenbondingand

increasedsurfacefunctionalization.Theseoxygengroups

can be responsible for increasing the hydrophilicity of the

Figure 1. FTIR-Attenuated total reflectance spectrum of 50-nm thick and

5-nm thick Nafion

®

thin films showing the change in the CF

3

(backbone) and

SO

3

/CF

3

(side chain) peak ratios with thickness.

Figure 2. Saturation profiles for baseline fresh (upper) and 2,666 hr aged

(lower) GDL/MEA packages at 60°C. Test conditions: 1.2 A/cm

2

, 95|95%

(An|Ca) constant inlet relative humidity for pressure tests, 150|150 kPa (An|Ca)

constant exhaust pressure for concentration gradient tests, constant flow rate at

an equivalent stoichiometry ratio of 2:2 at 1.2 A/cm

2

. Profiles are summed along

entire imaged area.

Gu – General Motors

V.G Fuel Cells / Transport Studies

V–154

DOE Hydrogen and Fuel Cells Program

FY 2014 Annual Progress Report

surface, increasing water retention and wicking action. Both

anode and cathode GDLs were tested, and the cathode GDL

was more affected by ageing. Finally, a GDL component

level multi-phase computational model has been developed to

address the need for meso-scale modeling within this media.

A statistical approach using percolation theory was used to

construct appropriate model porous domain structures, and

a Lattice-Boltzman approach was used to determine the

effective tortuosity and gas-diffusivity of these domains.

Additionally, X-ray microscopy was used to determine the

three-dimensional morphology of the GDL structure, which

can then be directly used as the computational domain in

the model. Future publications are being prepared based on

the results which demonstrate the prediction of effective

diffusivity and tortuosity for the real media morphology as a

function of saturation. This result can then be correlated and

linked with macroscopic performance models to obtain high-

speed predictive performance modeling with greater GDL

leveltransportdelity.

Transport in Flow Distributor Channels

The emergence of droplets and their interaction with

the reactant channel sidewall dictate trends of GDL-channel

interfacecoverage,two-phaseowpressuredrop,and

transitionofowpatterns.Thesetrendsaredependentonthe

cornerllingofthechannelbyliquidwater.Weconducted

exsituexperimentationtoestablishcorrelationstopredict

cornerllingbehaviorasafunctionofchanneldesign

parameters and operating conditions [10]. Liquid water was

injected into a single channel that was manufactured to

match baseline and auto-competitive designs. The distance

from water injection location on the GDL to the channel

side wall, materials of GDL and channel walls, corner angle

inanauto-competitivechannel,andsupercialairvelocity

in the channel were varied. A channel corner angle of 50°

is suggested for improved water removal characteristics.

Moreover, correlations were established to predict the corner

llingbehaviorandtwo-phaseowpressuredropatthe

instant of droplet removal. A force balanced model has also

been developed to provide further insight into the dynamics

of the droplet at the time of its interaction with the channel

side wall. Consequently, a channel design was suggested to

minimize the buildup of liquid water.

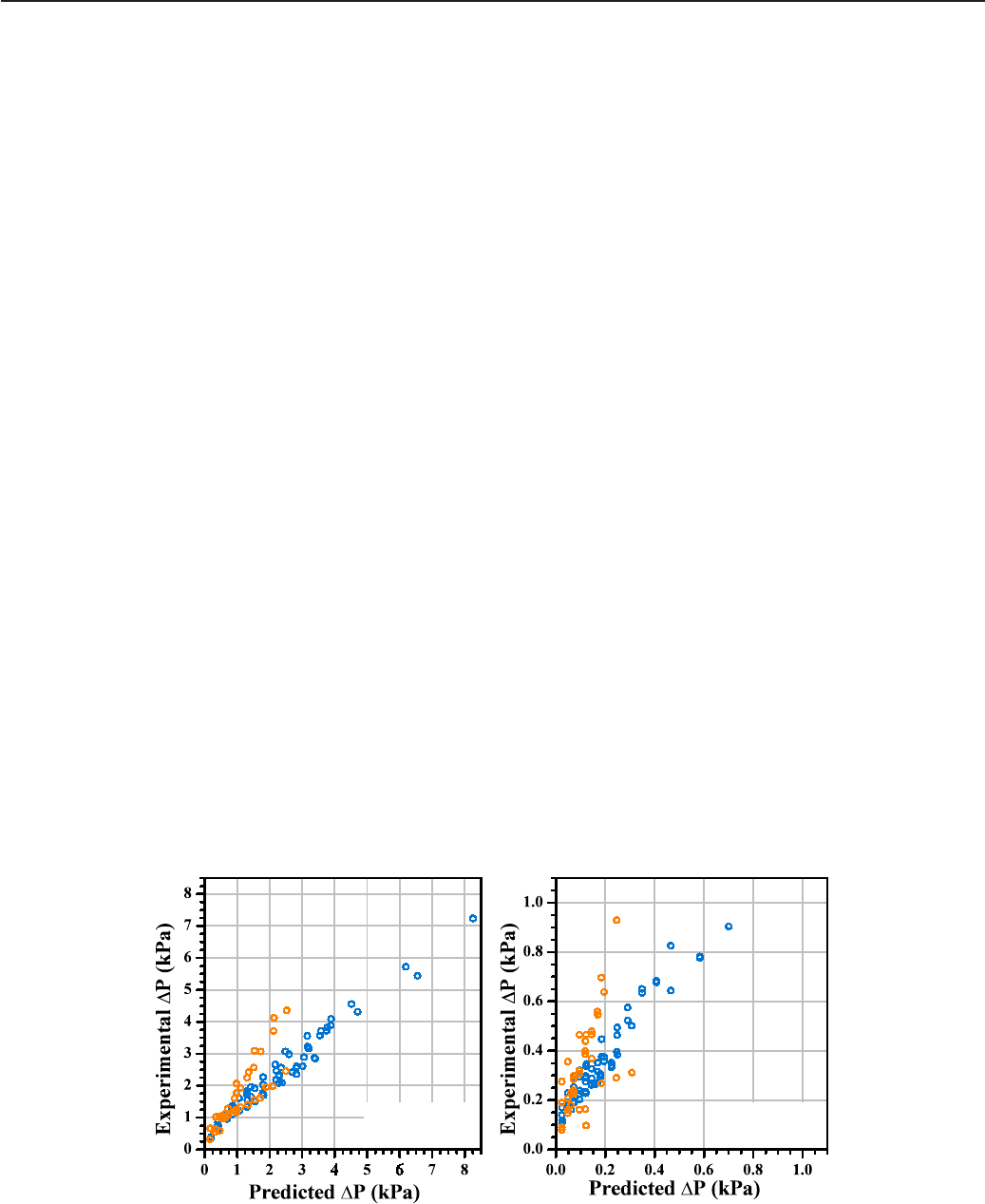

Two-phase pressure drop studies from the literature

havefocusedonthefundamentalfactorsthatinuencethe

two-phaseow.However,theconditionsinthePEMFC

reactant channels are unique as there is consumption of

gaseous reactants along the length and water is continuously

introduced through the GDL. This results in a continuously

changingqualityofthetwo-phasemixture.Thereare

temperature gradients both along the length of the channel as

well as the cross section of the cell, resulting in evaporation

and condensation-driven mass transport in these directions.

A step-wise elemental modeling scheme that allows ease of

integration into the down-the-channel performance model

has been proposed, developed and validated for the prediction

of two-phase pressure drop in the reactant channels. The

modeling scheme has been tested with several fundamental

pressure drop models available in the literature. It is found

thatthemodiedEnglishandKandlikarmodel[11]works

best to predict two-phase pressure drop in PEMFC reactant

channels. Figure 3 shows that it has a mean error of 11.6%

and 40.2% for cathode and anode, respectively, over the

entire range. A mean error of 5.2% was observed for the

cathodewithafullyhumidiedinlet.

In investigating channel-scale water transport and

accumulation, both within the fuel cell active area and in

thenon-activeareasextendingallthewaytotheanodeand

Figure 3. Comparison between the modified English and Kandlikar correlation and experimental data. Cell

temperature 40°C, Orange – 0% relative humidity Inlet, Blue – 95% relative humidity Inlet, (left) Cathode Side

Pressure Drop (right) Anode Side Pressure Drop.

Anode

Cathode

V–155

FY 2014 Annual Progress Report

DOE Hydrogen and Fuel Cells Program

V.G Fuel Cells / Transport Studies

Gu – General Motors

cathodeexitmanifolds,wecarriedoutexsitutwo-phase

owexperimentstounderstandpressuredropperformance

over a wide range of simulated operating conditions,

coupledwithinsituexperimentsapplyingneutronimaging

to directly measure fuel cell water content under low

temperature conditions in the range of 20 to 40

o

C [12]. It

was observed that the active area water volume is strongly

dependent on cell temperature, and temperature variation of

aslittleas0.5°Ccanproduceasignicantchangeinwater

accumulation,whichisalsoreectedinthecellvoltage.In

general, active area water decreases with increasing current

density. However, the water quantity is a function of both

cell temperature and anode/cathode pressure. Conversely,

the anode non-active water is weakly dependent on current

density, presumably because in this region there is little

drivingforcetoremovewateronceitispresent.Thisnding

has obvious implications relative to fuel cell operation

underfreezingconditions,andisindicativeofthedifculty

ofremovinganodeexitwaterduringshut-downpurge.

Furthermore,asignicantpressuredropwasseenovernon-

active area. On average, the outlet region contributes more

to the total (manifold-to-manifold) pressure drop for higher

waterowrates,suggestingthatwatermitigationstrategies

should focus on outlet non-active area as well as channel-to-

manifold interface, especially on anode side.

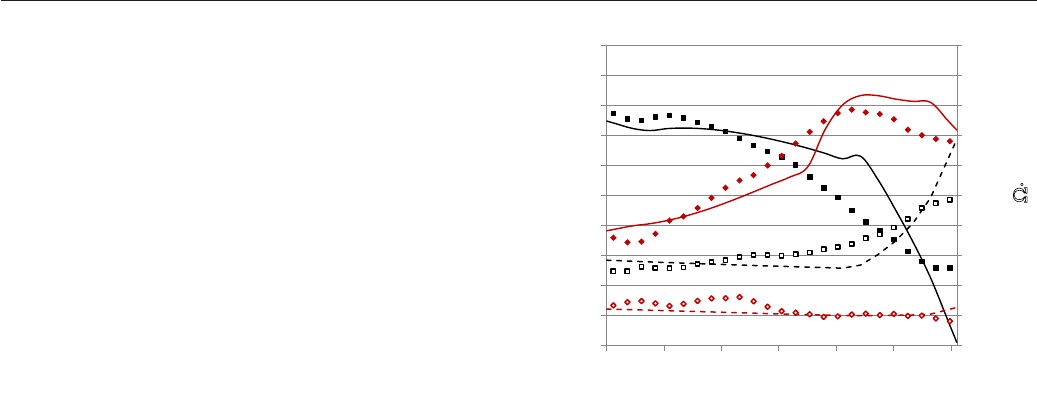

Modeling

The two-phase, 1+1D down-the-channel model has been

improvedandtestedagainsttheexperimentaldatagenerated

from baseline, baseline with low Pt-loaded cathode, and auto-

competitivematerialsets.Duetolackofexperimentaldata

on liquid water saturation within an electrode, the electrodes

are allowed to be supersaturated and water saturation therein

is evaluated based on local relative humidity by an empirical

correlation.Usingasinglesetofparameters,themodel

agrees fairly well to all three data sets. Figure 4 compares the

predicted down-the-channel current and HFR distributions

withthemeasuredones.Signicantly,themodelcapturesthe

opposite trends in current density distribution observed for

the automotive competitive and baseline materials plus low-

loaded Pt material sets, that is caused by the highly tortuous

anode diffusion media in the automotive competitive data

set. However, the agreement for the automotive competitive

material set comes with a compromise in the agreement

for the baseline material set. More work is needed to

achieve better quantitative agreement in down-the-channel

distributions.

A parametric study was performed for cell component

optimization based on the parametric study cell validation

data using the two-phase, 1+1D down-the-channel model.

Thedesignforsixsigmaapproachwasemployedtond

optimal material properties for better cell performance [13].

Among numerous input parameters, eight were chosen to

be the control factors. For the operating condition given in

Figure 4, the following recommendation can be made for cell

component properties in reference to the baseline materials:

Thinner membrane (12 microns)•

50% lower membrane water permeability•

25% less tortuous supporting layer in the ePTFE-•

reinforced membrane

25% less tortuous GDL in the presence of liquid water•

2X GDL thermal conductivity•

2X MPL thermal conductivity•

2X coolant-to-plate thermal resistance•

50%lowerlocaloxygentransportresistance•

CONCLUSIONS AND FUTURE DIRECTIONS

A well-organized characterization, modeling and

validation framework was developed early in this project.

Therstphase(FY2011)ofexecutionwaslargelyfocused

onexperimentaldevelopment.Thefocusgraduallyshiftedto

model development while continuing to complete validation

data.Duringthenalphaseoftheproject(FY2014),results

from these methods were described with multidimensional

component models and summarized in a down-the-channel

model that is compared to a comprehensive validation

database.SpecichighlightsfromFY2014:

A new validation data set based on the baseline materials •

with low Pt-loaded cathode added to the database for

model validation.

Figure 4. Comparisons between model and data for down-the-channel

current and HFR distributions. Squares represent baseline materials with

low Pt-loaded cathode (0.1 mgPt/cm

2

); and diamonds stand for Auto-

Competitive material set. The cell operates with H

2

/Air at stoichimetry 1.5/2.0,

100/150 kPa-abs outlet pressure, 60°C coolant out temperature, 0/95% inlet

relative humidity.

0.05

0.06

0.07

0.08

0.09

0.10

0.11

0.12

0.13

0.14

0.15

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

0 3 6 9 12 15 18

HFR (Ω⋅cm²)

Current Density (A/cm²)

Distance from cathode inlet (cm)

Symbols

- data

Lines - Model

Gu – General Motors

V.G Fuel Cells / Transport Studies

V–156

DOE Hydrogen and Fuel Cells Program

FY 2014 Annual Progress Report

layer of PEM fuel cells,” International Journal of Heat and Mass

Transfer, 71(10), pp. 585-592 (2014).

9. Kandlikar, S.G., E.J.See, M. Koz, P. Gopalan, R. Banerjee, “Two-

PhaseFlowinGDLandReactantChannelsofaProtonExchange

Membrane Fuel Cell,” International Journal of Hydrogen Energy, 39

(12), pp. 6620-6636 (2014).

10. Banerjee, R., and S.G. Kandlikar, “LiquidWaterQuantication

intheCathodeSideGasChannelsofaProtonExchangeMembrane

Fuel Cell Through Two-Phase Flow Visualization,” Journal of

Power Sources, 247, pp. 9-19 (2014).

11. Gopalan, P., and S.G. Kandlikar, “Modeling Dynamic

Interaction Between an Emerging Water Droplet and the Sidewall of

a Trapezoidal Channel,” Colloids and Surfaces A: Physicochemical

and Engineering Aspects, 441, pp. 267-274 (2014).

12. Gopalan, P., and S.G. Kandlikar, “Effect of Channel Materials

and Trapezoidal Corner Angles on Emerging Droplet Behavior in

ProtonExchangeMembraneFuelCellGasChannels,” Journal of

Power Sources, 248, pp. 230-238 (2014).

13. Banerjee, R., E.J. See, and S.G. Kandlikar, “Pressure Drop

and Voltage Response of PEMFC Operation under Transient

Temperature and Loading Conditions,” ECS Transactions, 58(1), pp.

1601-1611 (2013).

14. See, E.J., and S.G. Kandlikar, “Effect of GDL Material on

Thermal Gradients along the Reactant Flow Channels in PEMFCs,”

ECS Transactions, 58(1), pp. 867-880 (2013).

15. Xu, G., LaManna, J., and Mench, M.M., “Measurement of

Thermal Conductivity of Partially Saturated Diffusion Media under

Compression,” 2014 ECS Spring meeting, Toronto, Canada, May

12–16, 2014.

16. LaManna, Jacob M., Matthew M. Mench , “ Flow Field and

DiffusionMediaTortuosityInuencesonPEFCWaterBalance,”

Accepted for invited oral presentation. 2014 ECS and SMEQ Joint

InternationalMeeting,Cancun,Mexico,October5–10,2014.

17. LaManna,Jacob M., Daniel S. Hussey, David L. Jacobson,

Matthew M. Mench, “Role of Land Drainage on Water Storage in

PolymerElectrolyteFuelCellsUsingHighResolutionNeutron

Imaging,” Accepted for poster presentation.10

th

World Conference

on Neutron Radiography. Grindelwald, Switzerland, October 5–10,

2014.

18. Fenton, D.J., J.J. Gagliardo and T.A. Trabold, “Analysis of water

morphology in the active area and channel-to-manifold transitions

of a PEM fuelcell,” submitted for publication in Proceedings of the

ASME 8

th

International Conference on Energy Sustainability &

12

th

International Fuel Cell Science, Engineering and Technology

Conference, Paper ESFuelCell2014-6565, Boston, MA, June 30 –

July 2, 2014.

REFERENCES

1.Gu,W.,Baker,D.R.,Liu,Y.,Gasteiger,H.A.,“Protonexchange

membrane fuel cell (PEMFC) down-the-channel performance

model,” Handbook of Fuel Cells - Volume 5, Prof. Dr. W. Vielstich

et al. (Eds.), John Wiley & Sons Ltd. (2009).

2. Owejan, J.P., 2011 Annual Progress Report for the DOE

Hydrogen and Fuel Cells Program (2011).

Coninuedstudiesonthinionomerlmsandionomer-•

substrate interactions.

Neutron imaging data on liquid water saturation within •

GDLfortheeffectsofGDLtype,aging,andoweld

shows the impact of GDL surface properties and heat

transfer.

Validatedoweldpressuredropmodelincludesthe•

effects of water droplet-channel corner interaction, liquid

waterowpattern,andlocaloperatingcondition.

Signicantpressuredropoccursinthenon-active,•

channel-to-manifold region due to liquid water

accumulation therein; peak active area water volume

existslikelyduetogasmomentumandhydraulicforce

balance.

Down-the-channel 1+1D model improved with new •

relationships integrated, and the opposite trend in down-

the-channel current distribution associated with auto-

competitive material set successfully captured.

A parametric study performed for cell component •

optimization, and optimal material properties

recommended for better cell performance.

TheprojectendedinMay2014.Analreportisforthcoming.

FY 2014 PUBLICATIONS/PRESENTATIONS

1. Petrina, S.A. “Water Sorption, Viscoelastic, and Optical

Properties of Thin NAFION

®

Films.” Ph.D. Dissertation,

PennsylvaniaStateUniversity,2013.

2. Kusoglu, A., D. Kushner, D.K. Paul, K. Karan, M.A. Hickner,

A.Z.Weber,“ImpactofSubstrateandProcessingonConnement

ofNaonThinFilms,”Advanced Functional Materials 2014,

DOI: 10.1002/adfm.201304311.

3. Zimudzi, T.J., M.A. Hickner, “FTIR Analysis of Alignment in

NAFION® Thin Films at SiO

2

and Au Interfaces,” submitted to

J. Phys. Chem. B (2014).

4. Kushner, D.I., M.A. Hickner, “FTIR Analysis of Alignment in

NAFION® Thin Films at SiO

2

and Au Interfaces,” submitted to

Langmuir (2014).

5.LaManna,J.M.,J.M.Bothe,F.Y.Zhang,andM.M.Mench,

“Measurement of Capillary Pressure in Fuel Cell Diffusion Media,

Micro-Porous Layers, Catalyst Layers, and Interfaces,” submitted to

J. Power Sources (2014).

6. LaManna, J.M., Chakraborty, S., Gagliardo, J.J., and

Mench, M.M., “Isolation of transport mechanisms in PEFCs

using high resolution neutron imaging,” International Journal of

Hydrogen Energy, 39(7), pp. 3387-3396 (2014).

7. Xu, G., LaManna, J.M., Clement, J.T., and Mench, M.M., “Direct

measurement of through-plane thermal conductivity of partially

saturated fuel cell diffusion media,” Journal of Power Sources, 256,

pp. 212-219 (2014).

8.Owejan,J.P.,Trabold,T.A.,andMench,M.M.,“Oxygentransport

resistance correlated to liquid water saturation in the gas diffusion

V–157

FY 2014 Annual Progress Report

DOE Hydrogen and Fuel Cells Program

V.G Fuel Cells / Transport Studies

Gu – General Motors

10. Gopalan, P., and S.G. Kandlikar, “Effect of Channel Materials

and Trapezoidal Corner Angles on Emerging Droplet Behavior in

ProtonExchangeMembraneFuelCellGasChannels,” Journal of

Power Sources, 248, pp. 230-238 (2014).

11.GrimmM.,E.J.See,andS.G.Kandlikar,“Modelinggasow

in PEMFC channels: Part I – Flow pattern transitions and pressure

dropinasimulatedexsituchannelwithuniformwaterinjection

through the GDL,” Int. J. Hydrog. Energy, 37(17), pp. 12489-12503

(2012).

12. Fenton, D.J., J.J. Gagliardo and T.A. Trabold, “Analysis of water

morphology in the active area and channel-to-manifold transitions

of a PEM fuelcell,” submitted for publication in Proceedings of the

ASME 8

th

International Conference on Energy Sustainability &

12

th

International Fuel Cell Science, Engineering and Technology

Conference, Paper ESFuelCell2014-6565, Boston, MA, June 30 –

July 2, 2014.

13.KaiYangandElHaik,Design for Six Sigma, McGraw-Hill,

2003.

3. Owejan, J.P., Gagliardo, J.J., Sergi, J.M., Kandlikar, S.G.,

Trabold, T.A., “Water management studies in PEM fuel cells, Part

I: Fuel cell design and in situ water distributions,” International

Journal of Hydrogen Energy, 34 (8), 3436-3444 (2009).

4.http://www.pemfcdata.org/data/Standard_Protocol.xls.

5. Zimudzi, T.J., M.A. Hickner, “FTIR Analysis of Alignment in

NAFION® Thin Films at SiO2 and Au Interfaces,” submitted to J.

Phys. Chem. B (2014).

6. Kushner, D.I., M.A. Hickner, “FTIR Analysis of Alignment in

NAFION® Thin Films at SiO2 and Au Interfaces,” submitted to

Langmuir (2014).

7. Kusoglu, A., D. Kushner, D.K. Paul, K. Karan, M.A. Hickner,

A.Z.Weber,“ImpactofSubstrateandProcessingonConnement

ofNaonThinFilms,”Advanced Functional Materials 2014,

DOI: 10.1002/adfm.201304311.

8. Xu, G., LaManna, J.M., Clement, J.T., and Mench, M.M., “Direct

measurement of through-plane thermal conductivity of partially

saturated fuel cell diffusion media,” Journal of Power Sources, 256,

pp. 212-219 (2014).

9.LaManna,J.M.,J.M.Bothe,F.Y.Zhang,andM.M.Mench,

“Measurement of Capillary Pressure in Fuel Cell Diffusion Media,

Micro-Porous Layers, Catalyst Layers, and Interfaces,” submitted to

J. Power Sources (2014).